The aim of this research is to develop a dynamic model of an industrial EAF process and investigate its application for optimal EAF operation. Furnace charging Melting Refining De-slagging Tapping Furnace turn-around Modern operations aim for a tap-to-tap time of less than 60 minutes.

Electric Arc Furnace Industrial Efficiency Technology Measures

PDF - 73793 KB Laser tracking and tram control of a.

. SMS SIEMAG Submerged-Arc Furnaces and Electric Smelters 8 A WIDE RANGE OF DESIGN SERVICES We have designed a large variety of sub-merged-arc furnaces and electric smelters adapted to suit the individual requirements of the customer. Process is lower compared to the open arc process. 5 Design Criteria For the ModemUHP Electric New Tools for Improved Operation of High Arc Fumece W t h Auxiliaries Be man K Efficiency ElectricArc FurnacesAderup M 2 Gottardi R 3rd European Electric tee1 Congress 1989.

The compact design makes it easier to seal the furnace for improved energy recovery from the process gases. This book presents systematic and complete details on the current state of knowledge about metallurgical processes carried out in the electric arc furnace. These references are highly.

Download Free PDF Download PDF Download Free PDF View. In order to change the input active power of the EAF transformer TF MVLV is used. The electric arc furnace EAF is a highly energy intensive process used to convert scrap metal into molten steel.

2 Introduction to Electric Arc Furnace Steelmaking 21 Basic Concepts The Electric Arc Furnace EAF is today the most common way to recycle steel from scrap. Instabilities in electric steelmaking furnace arcs cause electrical and acoustical noise reduce operating efficiency increase refractory erosion and increase electrode usage. Understanding Electric Arc Furnace Operations.

Many fur-naces many features. PDF - 73793 KB File Type. Design of an experimental electric arc furnace 1992.

The electrical model of the EAF can be described as a non-linear 3-phase electric circuit whose main non-linearities are represented by the electric arcs. This great variety of our designs is described below. The aforementioned components have been calculated step-by-step.

By Hartman Alan D. The more compact furnace design the higher powerdensity and the far lower electrical loss in the furnace secondary system compensate for this increased energy loss. The operating current has been.

Design of submerged arc furnaces with particular reference to production of high-silicon alloys by TE. Math-ematically the electric arc can be described as an impedance load whose resistance Ra can be mod-eled by means of the well-known Cassie-Mayr model 1 2 3 from Eq. With this background the United Nations Development Programme UNDP had entrusted The Energy and Resources.

There is a broad variety of steel scrap both in terms of composition from plain carbon steel through to highly alloyed tool steel and geometry from finely shredded sheet through to. The importance of electric arc furnace steelmaking is evident from the escalated world production seen in steel industry. Some twin shell furnace operations are achieving tap-to-tap times of 35 to 40 minutes.

The rst contribution is developing. Shows that it employs electric arc furnaces of varying capacities vintages and energy performance. 32 Furnace design 18 321 Ultra High Power transformer 18 322 High-impedance system 19 323 Aluminium electrode arm 21.

2 Arc Furnace Electric Circuit Obtaining the furnace operating current is a complex task since it must take into account all the electric circuit impedance components starting from the utility line and ending at the furnace electrodes. In this figure bus 1 is the point of common coupling PCC which is the supplying bus of the EAF transformer. Share raw materials operation typical equipment off-gas treatment emissions.

Large number of electric reduction furnaces and published the result of his work on several occasions during the 1970s Westly 1974 1975 1979. The Model of Power System with Ac Electric Arc Furnace The electric diagram of a source supplying an EAF is illustrated in Figure 1. The electric arc furnace operating cycle is called the tap-to-tap cycle and is made up of the following operations.

This work has three main contributions. In this chapter electric steelmaking is introduced with a short review.

Pdf Modeling Of Electric Arc Furnaces Eaf With Electromagnetic Stirring Semantic Scholar

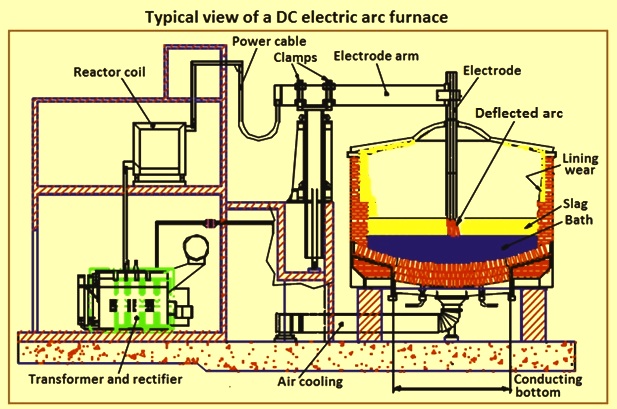

Dc Electric Arc Furnace Ispatguru

Design And Prototype Development Of A Mini Electric Arc Furnace Semantic Scholar

Design Features Of An Ac Electric Arc Furnace Ispatguru

Pdf Modelling And Control Of A Three Phase Electric Arc Furnace Semantic Scholar

Electric Arc Furnace Electrical4u

Electric Arc Furnace Design Operation And Working Principle Bright Hub Engineering

0 comments

Post a Comment